+

+ Construction Consolidation Centres offer opportunities to improve operational efficiency, which results in reduced congestion, delays and improved safety.

The growing population and strong economic performance have led to a significant increase in demand for new homes, commercial spaces, and transport infrastructure.

To meet this demand safely and efficiently, the construction industry must take a creative approach to logistics management.

Major construction projects face considerable challenges managing the number of deliveries each day. Consolidation combines and coordinates ‘just-in time’ deliveries. By streamlining logistics, these strategies can reduce congestion and delays while enhancing operational efficiency and safety.

What are Construction Consolidation Centres?

Construction Consolidation Centres are appropriately located distribution facilities where multiple bulk material deliveries are stored and transported to construction sites.

How CCC’s function

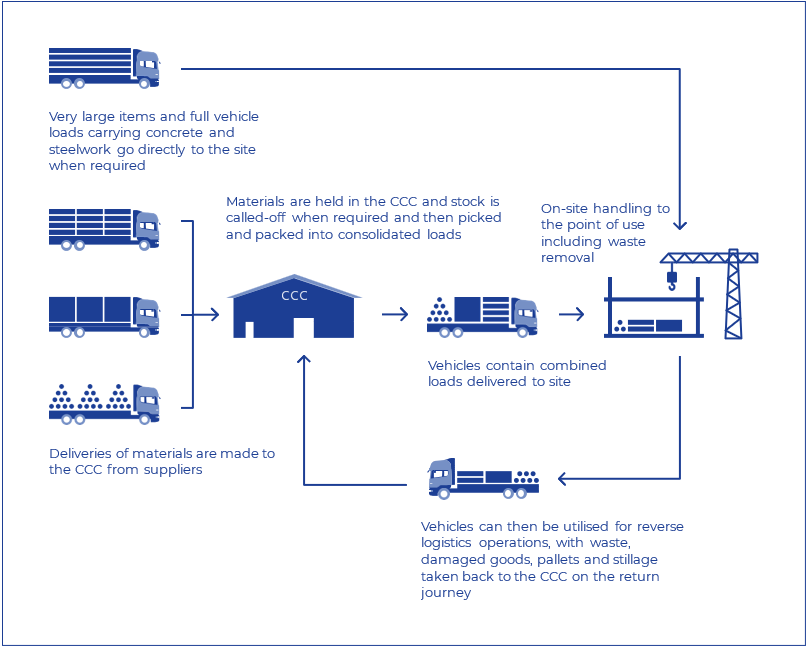

- Deliveries of materials are made to the CCC from suppliers

- Materials are checked to ensure they are as specified and damage-free

- Materials are held in the CCC, and stock is called-off when required and then picked and packed into consolidated loads

- Vehicles can then be utilised for reverse logistics operations, with waste, damaged goods, pallets and stillages taken back to the CCC on the return journey

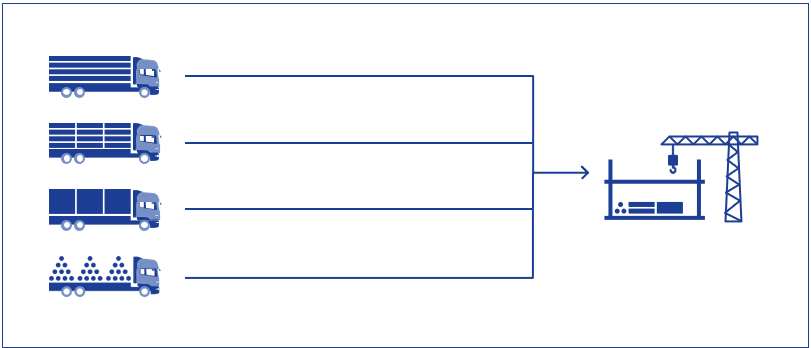

Figure 1 – Process with no Consolidation Centre, which leads to substantially increased road congestion from more vehicles delivering to construction sites.

Figure 2 – Consolidation process maximises efficiency and leads to an overall reduction in vehicle numbers delivering to often restricted and congested environments.

Benefits

Benefits of CCC Services to Construction Supply Chains:

- Materials held in controlled conditions

- Visibility of stock for call-off

- Single point of contact for materials

- Better control and visibility of the supply chain

- Quick response to urgent requests

- Ability to perform additional processing off-site

- Less damage and waste due to reduced handling

- Delivery efficiency due to better load fill

Operational Efficiency Improvements:

- Reduced delivery costs due to fewer vehicle freight miles from bulk load deliveries using edge-of-town CCCs

- Better utilisation of cranes and material handling equipment

- Faster vehicle turnaround times

- Availability of materials means less time and space wasted at site

- Less damage and over ordering of materials

- Utilisation of delivery vehicles for reverse logistics tasks

Environmental Benefits:

- Using CCCs will reduce construction waste and vehicle emissions

- Fewer vehicles means less construction traffic

- Reduced vehicle emissions, noise and pollution

Vehicle Efficiency

- Construction Consolidation Centres can store and deliver fully loaded vehicles to sites when required, maximizing delivery capacity and reducing the number of trips

Increased Delivery Reliability

- Deliveries from CCCs to construction sites can significantly improve reliability

- Example: At a London CCC, 97% of deliveries (correct type and quantity) arrived within 15 minutes of the scheduled time

- Without a CCC, only 39% met that standard

(London Construction Consolidation Centre – Final report – 2008)

Reverse Logistics

- Delivery vehicles can also be used for collecting unused materials and waste on their return journey, reducing collection costs.

- Reverse logistics activities can utilise delivery vehicles for collecting unused materials and waste, reducing collection costs

Avoiding Congestion

- CCCs provide alternatives outside the city centre, helping to avoid heavily congested areas and improve delivery times

Reduced construction cost

- Consolidation services are already a permitted condition for certain large scale developments. Forming part of an overall logistics strategy to gain planning permission and comply with Construction Logistics Plan (CLP) guidance

- CCCs reduced losses and damages by between seven and 15%2 in Heathrow T5 due to less material damage and shrinkage

- CCCs can support businesses’ cost savings through facilitating purchasing economies of scale and programme resilience

Improved programme efficiency

- Delivery efficiency: reduced risk of project over-run with improved delivery reliability. Also supports On-time In Full (OTIF) deliveries

- Better control and visibility of the supply chain: simplified supply chain management with a single point of contact

- Increased on-site productivity: on site space requirements for vehicles and the storage of materials are reduced

- Less time waiting for materials

Less vehicles and better control means:

- Less emissions: CCCs support London’s sustainability targets, through reducing construction vehicle road miles

- Less safety risk: increased safety during last mile deliveries from FORS and CLOCS vehicles which use safer specification vehicles. CCCs led to fewer journeys, reduced road miles and lower collision risks

- Less congestion: use of a CCC can reduces vehicle deliveries to site and on London’s busy roads

- Less noise: construction vehicle activity and environmental impacts on neighbours is reduced, including heavy goods vehicle (HGV) movements

Core and Specialist Services Offered at Construction Consolidation Centres

- Receipt, storage, order picking, packing, kit building, palletisation, delivery and reverse logistics returns

- CCCs can also provide bespoke services such as: stevedoring, fit out mock-ups, fabrication, security screening, container handling and off-site construction

- This is typically supported by equipment such as balers, trailer shunters, alongside routing services and scheduling transport management systems

Resources

- Construction Consolidation Centres – An assessment of the potential for London wide use

- London Construction Consolidation Centre – Final report – 2008

- Construction logistics – Models for consolidation

- Rethinking Deliveries – TFL Summary Report

- CILT 2017 the need for LCCC

- Designing Building Wiki – Construction Consolidation Centres

- Freight Consolidation Centre Study – TTR & TRL – 2010

- Construction Consolidation Centres in North Kent – Needs Analysis and Feasibility Study – 2007

- London Freight Consolidation Feasibility Study & Case studies – 2019

Want to contribute to this page?

To learn more, contribute to this page or have any case studies at your Construction Consolidation Centre? Please contact CLOCS at support@clocs.org.uk.